Cable Cross -Section

Feature:

- Perfect cable structure with high fiber density

- Accurate fiber length balance to ensure stable performance

- No gel in cable core for water blocking

- Sheath structure innovation to enhance blowing performance

- Greater blowing distance

- Fiber: G.G652D, G.657A1, G.657A2

Standards:

- Unless otherwise specified in this specification, all requirements shall be mainly in accordance with the following standard specifications.

- Optical fiber:ITU-T G.652D、IEC 60794-2-50

- Optical cable :IEC 60794-5、IEC60794-1-2

Specification:

| Fiber count (F) | Nominal diameter (mm) | Nominal weight (kg/km) | Max tensile strength (N) | Temperature (℃) |

| 12 | 5.2±0.1 | 25 | 500 | -40 to +70 |

| 24 | 5.2±0.1 | 25 | 500 | |

| 36 | 5.2±0.1 | 25 | 500 | |

| 48 | 5.2±0.1 | 25 | 500 | |

| 60 | 5.2±0.1 | 25 | 500 | |

| 72 | 5.2±0.1 | 25 | 500 | |

| 96 | 6.1±0.1 | 35 | 1000 | |

| 144 | 7.9±0.1 | 57 | 1200 | |

| 192 | 7.9±0.1 | 55 | 500 | -20 to +70 |

| 216 | 7.9±0.1 | 55 | 500 | |

| 288 | 9.4±0.1 | 78 | 1000 |

Blowing Test:

| Fiber count (F) | Blowing machine | Suitable microduct (mm) | Blowing distance in 10/8 duct (m) | Blowing distance in 12/10 duct (m) | Blowing distance in 14/12 duct (m) |

| 12 to 72 | PLUMETTAZ PR-140 MiniJet-400 15bar | 10/8 or 12/10 | 1800 | 2300 | / |

| 96 | 10/8 or 12/10 | 1800 | 2300 | / | |

| 144 | 12/10 | / | 1200 | / | |

| 192 to 216 | 12/10 | / | 1500 | / | |

| 288 | 14/12 | / | / | 1500 |

Mechanical Performance:

| Item | Testing Method | Testing Results | Specified Value | |

| Tension performance | IEC 60794-1-2-E1 | Optical fiber strain | Additional attenuation | Max. Tensile Strength = Short term Allowable tension ≈3×(Long term Allowable Tension) |

| Short term:≤0.3% Long term:≤0.1% | Short term:<0.1 dB, reversible; Long term:≤0.03 dB | |||

| Crush | IEC 60794-1-2-E3 | Short term:<0.10 dB, reversible; Long term:≤0.03 dB; The outer sheath has no visible crack. | Short term crushing force =800 N Long term crushing force =400 N | |

| Repeated bending | IEC 60794-1-2-E6 | After test, ≤0.03 dB; The outer sheath has no visible crack. | R=20 outer Φ | |

| 24~72:Bending load =50N | ||||

| 96~144:Bending load =100N | ||||

| Bending times =30 | ||||

| Torsion | IEC 60794-1-2-E7 | After test, ≤0.03 dB; The outer sheath has no visible crack. | Torsion angle=±180º | |

| 24~72:Torsion load =50N | ||||

| 96~144: Torsion load =100N | ||||

| Torsion times =10 | ||||

| Cable bend | IEC 60794-1-2-E11A | After test, The optical fiber can’t be broken; The outer sheath has no visible crack. | R=20 outer Φ 10Turns Cycles times =5 | |

| All optical testing proceeded at 1550 nm | ||||

Environment Performance:

| Item | Testing Method | Testing Results | ||

| Temperature cycling | IEC 60794-1-2-F1 | Allowable additional attenuation (1550nm) | ||

| G.652B | G.652D | G.655 | ||

| ≤0.10 dB/km, reversible; | ||||

| Water penetration | Water column: 1m, 1m cable, Period:24 hours | No water leak through the open end of cable | ||

| Filling compound flow | 70℃,Period:24 hours | No compound flow from the cable | ||

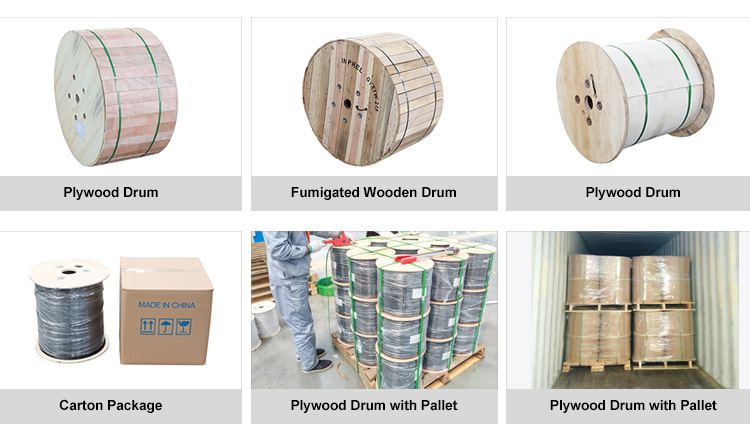

Packing and Marking:

- Each single length of cable shall be reeled on Fumigated Wooden Drum

- Covered by plastic buffer sheet

- Sealed by strong wooden battens

- At least 1 m of inside end of cable will be reserved for testing.

- Drum length: Standard drum length is 3,000m±2%; as required

- 5.2 Drum Marking(can according to the requirement in the technical specification) Manufacturer name;

- Manufacturing year and month Roll—direction arrow;

- Drum length; Gross/net weight;

Packaging and Shipping: