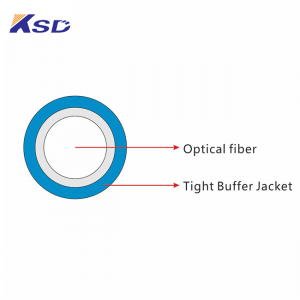

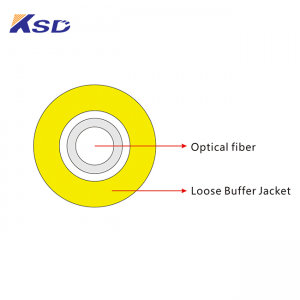

Cable Cross -Section

Feature:

- through up to 72 fibers for 6 mm ID micro-ducts

- Small diameter, lightweight and low friction sheath design

- stranding design allows for easy mid-span access and isolate

- fibers from installation and environmental rigors

- HDPE as outer sheath for increased blowing distance and fast.

- Ripcord added for easier sheath removal.

- Fiber options: SM (G652D, G657A), MM (OM1, OM2, OM3 & OM4)

- Higher fiber count cable designs are available on request.

Standards:

- Unless otherwise specified in this specification, all requirements shall be mainly in accordance with the following standard specifications.

- Optical fiber:ITU-T G.652D、IEC 60794-2-50

- Optical cable :IEC 60794-5、IEC60794-1-2

Technique Parameters:

| ITEM | Value |

| Fiber count | 6~72 Cores |

| Tube count | Up to 6 |

| Cable OD | 6.0±0.3mm |

| Loose tube OD | 1.65±0.05mm |

| Max. Tensile(Short term) | 600N |

| Max. Tensile(Long term) | 300N |

| Max. Crushing Resistance(Short term) | 1000N/100 mm |

| Max. Crushing Resistance(Long term) | 300N/100 mm |

| Sheath Material | Standard: HDPE. Optional: PE |

| Min. Bending Radius(Dynamic) | 20D |

| Min. Bending Radius(Static) | 10D |

| Strength Member | 1.6mm FRP |

| Standard Jacket Color | Black |

| Environmental Protection | RoHS COMPLIANT |

| Storage Temperature | -40~70ºC |

| Operation Temperature | -40~70ºC |

| Installation Temperature | 0 ~ 50ºC |

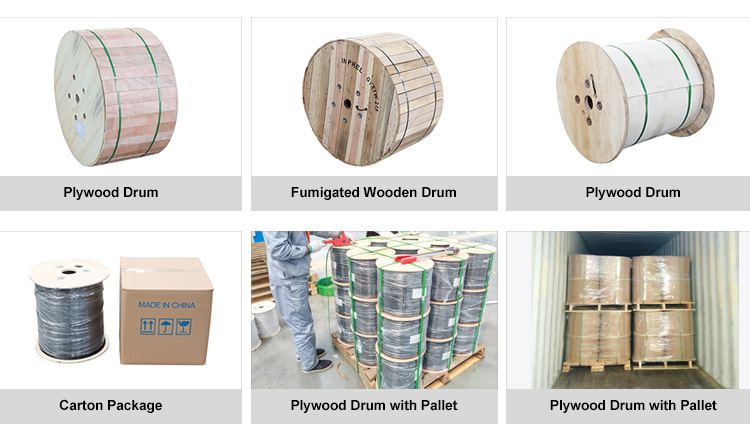

Packing and Marking:

- Each single length of cable shall be reeled on Fumigated Wooden Drum

- Covered by plastic buffer sheet

- Sealed by strong wooden battens

- At least 1 m of inside end of cable will be reserved for testing.

- Drum length: Standard drum length is 3,000m±2%; as required

- 5.2 Drum Marking(can according to the requirement in the technical specification) Manufacturer name;

- Manufacturing year and month Roll—direction arrow;

- Drum length; Gross/net weight;

Packaging and Shipping: