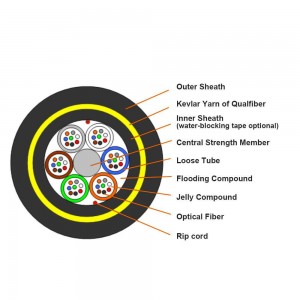

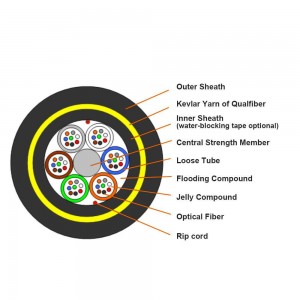

Cable Cross -Section

Applications:

Utilised for telecommunications by power utilities, telcos, and private network groups

Designed for installation on distribution lines

Characteristics:

ADSS aerial optical fiber cable is a kind of combined optical cable made by winding the optical fiber bundle on the central strength member, after insulation, waterproof, reinforcement, sheath, and other protective measures. ADSS cable is mainly installed on the existing 220kV or lower power line. Layer or central tube design. Ar amid yarn is used as a strength component to enhance tensile and strain properties. The outer sheath can be divided into PE and tracking resistance PE to correspond to space potentials lower than and greater than 12kV.

1. The cable diameter is small, the weight is light, the span can be 1500M, and the additional load on the tower is low.

2. High tensile strength, which can exceed 90KN.

3. Non-metal structure, good insulation performance, lightning protection.

4. The production process is sophisticated, the armed yarn is uniformly stressed, and has excellent stress-strain performance.

5. Excellent anti-gun action, best discharge corrosion performance.

6. It can constructed without power failure, and the power line failure does not affect the normal transmission of the aerial optical fiber cable.

7. Single-mode, multimode optical fiber and integrated optical cable design.

8. The sleek shape makes the optical cable have superior aerodynamic performance.

9. The all-media fiber optic cable structure is conducive to installation and maintenance.

10.Wide temperature adaptation range, small linear expansion coefficient, can meet the requirements of harsh environments.

Technical Parameter:

| SPAN(M) | ICE+WIND:0MM+35M/SEC | ICE+WIND:12MM+30M/SEC | ||||||

|---|---|---|---|---|---|---|---|---|

| CABLE O.D.(MM/IN) | CABLE WEIGHT (KG/KM)/(LB/KFT) | MAX.WORKING TENSION(N/LB) | MAX .SAG(%) | CABLE O.D.(MM/IN) | CABLE WEIGHT (KG/KM)/(LB/KFT) | MAX.WORKING TENSION(N/LB) | MAX .SAG(%) | |

| 100 | 13.9/5.472 | 152/102.01 | 7578/1704 | 2 | 13.8/0.543 | 150.0/100.67 | 6621/1489 | 2 |

| 200 | 14.3/0.562 | 161/108.05 | 10430/2346 | 3 | 14.1/0.555 | 157.0/105.37 | 9000/2024 | 3 |

| 400 | 15.9/0.625 | 199/133.56 | 23221/5223 | 3 | 15.4/0.606 | 187.0/125.50 | 19225/4331 | 3 |

| 500 | 16.7/0.657 | 220/147.65 | 30590/6881 | 3 | 16.1/0.633 | 204.0/136.91 | 24885/5598 | 3 |

| 600 | 16.3/0.641 | 209/140.27 | 26952/6063 | 4 | 15.7/0.618 | 196.0/131.54 | 22154/4983 | 4 |

| 800 | 16.5/0.649 | 216/144.97 | 29452/6625 | 5 | 15.9/0.625 | 201.0/134.90 | 24042/5408 | 6 |

| 1000 | 16.7/0.657 | 221/148.32 | 31271/7034 | 6 | 16.1/0.633 | 204.0/136.91 | 24407/5490 | 6 |

Mechanical Properties:

| Minimum Bending Radius: | Maximum Compressive Load: | 4000N | |

| Under installation: | 20×OD | Repeated Impact: | 4.4 N.m (J) |

| During operation | 10×OD for unarmoured cables | Twist (Torsion): | 180×10 times, 125×OD |

| 20×OD for armoured cables | Cyclic Flexing: | 100 cycles | |

| Temperature Range: | |||

| Operating Temperature Range: | -40℃(-40℉) to +70℃(+158℉) | Crush Resistance: | 263N/cm (1250lb/in) |

| Storage Temperature Range: | -50℃(-58℉) to +70℃(+158℉) |

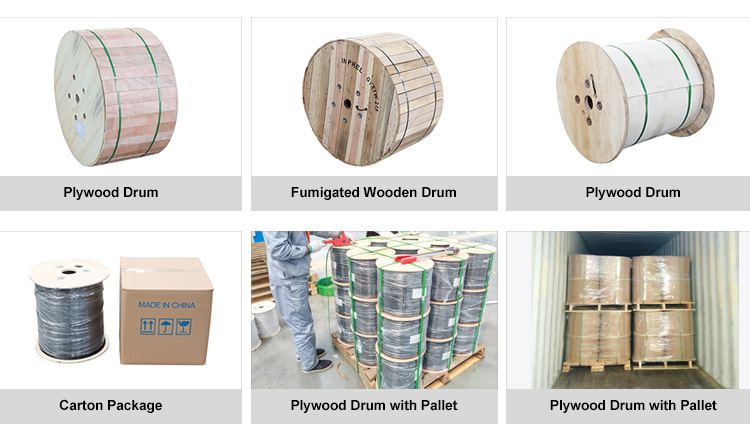

Packing and Marking:

- Each single length of cable shall be reeled on Fumigated Wooden Drum

- Covered by plastic buffer sheet

- Sealed by strong wooden battens

- At least 1 m of inside end of cable will be reserved for testing.

- Drum length: Standard drum length is 3,000m±2%; as required

- 5.2 Drum Marking(can according to the requirement in the technical specification) Manufacturer name;

- Manufacturing year and month Roll—direction arrow;

- Drum length; Gross/net weight;

Packaging and Shipping:

-

Long Span ADSS Fiber Optic Cable 200m-1000m

-

Mini Span ADSS Fiber Optic Cable 50-150m

-

48 Core Aerial Non Metallic ADSS Cable With HDP...

-

12 Core ADSS Optical Cable Self Supporting 100 ...

-

ADSS Double Suspension Clamp

-

ADSS Optical Cable Joint Box/Splice Closure/Joi...

-

ADSS Series Tension Clamp

-

ADSS/OPGW Down Lead Clamp

-

24 Core Single Jacket Aerial ADSS Fiber Optical...

-

Aerial Non-metal Double Jacket G652d ADSS Fiber...

-

All Dielectric Self Supporting Cable(ADSS) Cable

-

ASU(Mini ADSS) Aerial Self-Supported ASU Fiber ...