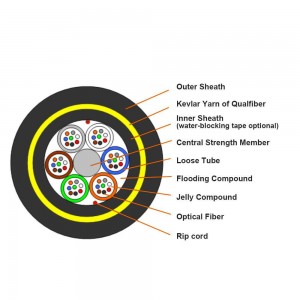

Cable Cross -Section

Fiber Type: G652D; G655C; 657A1; 50/125; 62.5/125; OM3; OM4 As Options

Span: 500-1500m

Application: Self-support Aerial installation

Main Features:

- Long Span Installation & Use

- Tailored designs span distances up to 2,500’ (760 m) without interrupting power

- Higher count designs utilize 24 fiber per tube to reduce environmental load

- Matching pole attachment hardware (dead-ends, suspension clamps)

Standards: Complies with IEEE 1222, IEC 60794-4-20, ANSI/ICEA S-87-640, TELCORDIA GR-20, IEC 60793-1-22, IEC 60794-1-2, IEC 60794

Characteristics:

| Parameters | Specification | |

| Optical Characteristics | ||

| Fiber Type | G652.D | |

| Mode Field Diameter (um) | 1310nm | 9.1 ± 0.5 |

| 1550nm | 10.3 ± 0.7 | |

| Attenuation Coefficient (dB/km) | 1310nm | ≤ 0.35 |

| 1550nm | ≤ 0.21 | |

| Attenuation Non-uniformity (dB) | ≤ 0.05 | |

| Zero Dispersion Wavelength ( λ0) (nm) | 1300 ~ 1324 | |

| Max Zero Dispersion Slope (S0max) (ps/(nm2·km)) | ≤ 0.093 | |

| Polarization Mode Dispersion Coefficient (PMDQ) (ps/km1/2) | ≤ 0.2 | |

| Cut-off Wavelength (λcc) (nm) | ≤ 1260 | |

| Dispersion Coefficient (ps/ (nm·km)) | 1288~1339nm | ≤ 3.5 |

| 1550nm | ≤ 18 | |

| Effective Group Index of Refraction (Neff) | 1310nm | 1.466 |

| 1550nm | 1.467 | |

| Geometric characteristic | ||

| Cladding Diameter (um) | 125.0 ± 1.0 | |

| Cladding Non-circularity (%) | ≤ 1.0 | |

| Coating Diameter (um) | 245.0 ± 10.0 | |

| Coating-cladding Concentricity Error (um) | ≤ 12.0 | |

| Coating Non-circularity (%) | ≤ 6.0 | |

| Core-cladding Concentricity Error (um) | ≤ 0.8 | |

| Mechanical characteristic | ||

| Curling (m) | ≥ 4 | |

| Proof Stress (GPa) | ≥ 0.69 | |

| Coating Strip Force (N) | Average Value | 1.0 5.0 |

| Peak Value | 1.3 ~ 8.9 | |

| Macro Bending Loss (dB) | Ф60mm, 100 Circles, @ 1550nm | ≤ 0.05 |

| Ф32mm, 1 Circle, @ 1550nm | ≤ 0.05 | |

Specifications:

| Parameters | Specification | ||||||

| Fiber Count | 2 | 6 | 12 | 24 | 60 | 144 | |

| Loose Tube | Material | PBT | |||||

| Fibers per Tube | 2 | 4 | 4 | 4 | 12 | 12 | |

| Numbers | 1 | 2 | 3 | 6 | 5 | 12 | |

| Filler Rod | Numbers | 5 | 4 | 3 | 0 | 1 | 0 |

| Central Strength Member | Material | FRP | FRP coated PE | ||||

| Water Blocking Material | Water blocking yarn | ||||||

| Additional Strength Member | Aramid yarns | ||||||

| Inner Jacket | Material | Black PE (Polythene) | |||||

| Thickness | Nominal: 0.8 mm | ||||||

| Outer Jacket | Material | Black PE (Polythene) or AT | |||||

| Thickness | Nominal: 1.7 mm | ||||||

| Cable Diameter (mm) | 11.4 | 11.4 | 11.4 | 11.4 | 12.3 | 17.8 | |

| Cable Weight (kg/km) | 94 ~ 101 | 94 ~ 101 | 94 ~ 101 | 94 ~ 101 | 119 ~ 127 | 241 ~ 252 | |

| Rated Tension Stress (RTS) (KN) | 5.25 | 5.25 | 5.25 | 5.25 | 7.25 | 14.5 | |

| Maximum Working Tension (40%RTS) (KN) | 2.1 | 2.1 | 2.1 | 2.1 | 2.9 | 5.8 | |

| Everyday Stress (15-25%RTS) (KN) | 0.78 ~ 1.31 | 0.78 ~ 1.31 | 0.78 ~ 1.31 | 0.78 ~ 1.31 | 1.08 ~ 1.81 | 2.17 ~ 3.62 | |

| Allowable Maximum Span (m) | 100 | ||||||

| Crush Resistance (N/100mm) | Short time | 2200 | |||||

| Suiting Meteorological Condition | Max wind speed: 25m/s Max icing: 0mm |

||||||

| Bending Radius (mm) | Installation | 20D | |||||

| Operation | 10D | ||||||

| Attenuation (After Cable) (dB/km) | SM Fiber @1310nm | ≤ 0.36 | |||||

| SM Fiber @1550nm | ≤ 0.22 | ||||||

| Temperature Range | Operation (℃) | -40 ~ +70 | |||||

| Installation (℃) | -10 ~ +50 | ||||||

| Storage & Shipping (℃) | -40 ~ +60 | ||||||

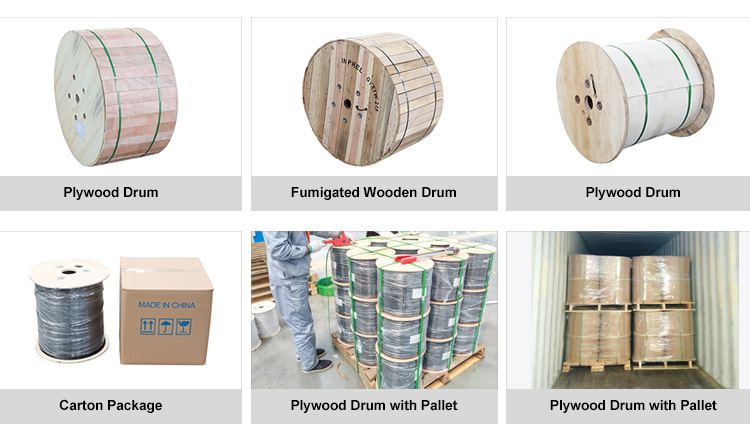

Packing and Marking:

- Each single length of cable shall be reeled on Fumigated Wooden Drum

- Covered by plastic buffer sheet

- Sealed by strong wooden battens

- At least 1 m of inside end of cable will be reserved for testing.

- Drum length: Standard drum length is 3,000m±2%; as required

- 5.2 Drum Marking(can according to the requirement in the technical specification) Manufacturer name;

- Manufacturing year and month Roll—direction arrow;

- Drum length; Gross/net weight;

Packaging and Shipping:

-

Long Span ADSS Fiber Optic Cable 200m-1000m

-

Mini Span ADSS Fiber Optic Cable 50-150m

-

48 Core Aerial Non Metallic ADSS Cable With HDP...

-

12 Core ADSS Optical Cable Self Supporting 100 ...

-

ADSS Double Suspension Clamp

-

ADSS Optical Cable Joint Box/Splice Closure/Joi...

-

ADSS Series Tension Clamp

-

ADSS/OPGW Down Lead Clamp

-

24 Core Single Jacket Aerial ADSS Fiber Optical...